updated august 2013

Sometimes you need to, when you have an old bike like mine and spareparts are hard to get (rear-wheel with 5-gear freewheel).

The only thing that can be tricky, is how to calculate the length of the spokes.

There are quite a few good homepages where people explain all about building wheels.

But I found some important things missing, so they will be on my page here:

1) A quick guide for mounting spokes, for when you have taken your wheel apart and need help to find out about the followingorder of your spokes.

2) A straightforward derivation of how to calculate spoke-length (inclusive all intermediate results!!!).

3) Logical explanation of the measurements you have to make in order to calculate spokelength, when you want to build your wheel from scratch.

The rest will be just referring to others with links; see at the lower end of this page.

#1 How to mount the spokes?

There is an easy pattern in the followingorder of the spokes in your wheel. When you have grasped that, it is easy to take out all the spokes and mount them again.

The pattern depends on 3 things:

- number of spokes

- number of spoke-crossings

- left- or righthand wheel

#1.1 number of spokes

The most rugged wheelbuild uses 36 spokes.

This is also the most used version, but nowadays people also build with 24 or even less spokes.

That is to decrease cost and weight (saving $1/sp for an expensive spoke, and 10gr/sp for a heavy spoke), but it will make the wheel less durable.

#1.2 number of spoke-crossings

The spokes are mounted with an angle compared to the shortest line between hub and rim.

Wheels where this angle is 0 degrees, are called radial wheels, and here the spokes don't cross at all. But radial wheels are not usable at all for rearwheels, so normally the wheels have crossings between a spoke and 2 or 3 other spokes.

Take a look at the big picture below, with the wheel with the red tire; the spoke #10 is crossing spoke #0, 4 and 8.

This is a wheel with 3 crossings and 36 spokes.

#1.3 left- or righthand wheel (or better explained: clockwise- or anticlockwise built wheel)

When mounting the spokes, you should always start next to the valve-hole, and get nearly parallel spokes on both sides of the valve.

That is in order to get enough space around the valve so it is easy to reach with a pump. The picture of the wheel with the red tire shows that there is more room between spoke #10 and 11 than between e.g. #8 and 9.

The spoke-holes in the rim have an offset to the hub-side where the spokes come from. And since it is easiest to mount the spokes that are on the top side (with the weel lying flat), you will start anticlockwise with a lefthand rim and clockwise with a righthand rim.

|

|

|

Now take a look again at the wheel with the red tire, in the picture below.

It has a lefthand rim, so the first spoke to mount (from the side you are looking from) is to the left of the valve and has the number #10 here.

This is a 36-spoke wheel, and the numbering is chosen just to make it easy to see the pattern;

- There are 9 spokes in between the two red spokes (the two adjacent crossing spokes on the hub).

- There are 3 spokes in between the red and the blue spoke (the two nearest spokes on the hub that go in the same direction).

With these two observations of the pattern, it is really easy to build the whole wheel ! (More details in the links at the end of this page)

#2 Derivation of how to calculate spokelenght

When looking at the spoke-pattern above, you can see the symmetry that can be used to calculate spoke-lenght.

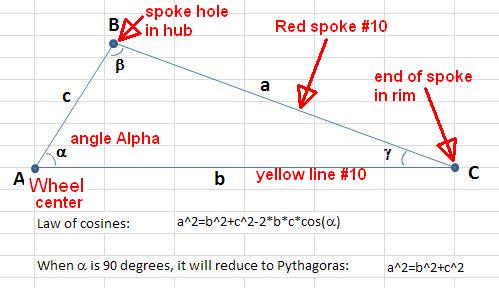

First, we can derive the angle between the red spokes and the middle yellow dotted line.

This enables us to derive the length of the spokes in the XY-plane (Z-axis is along the hub axle "sticking out of your screen"), when using the measured values of the hub and the rim along the yellow dotted lines.

Between the two red spokes and also the outer yellow dotted lines, there are 10 sections.

Each section covers 360degrees/36spokes=10degrees, so between the two yellow lines at #5 and #10 there is a 50degrees angle.

The startpoint of Spoke #10 in the hub-flange is not on the yellow line, but half a hole further to the left of the hub. Since there are 36/2=18 holes on each side of the hub, this adds 10degrees to the angle.

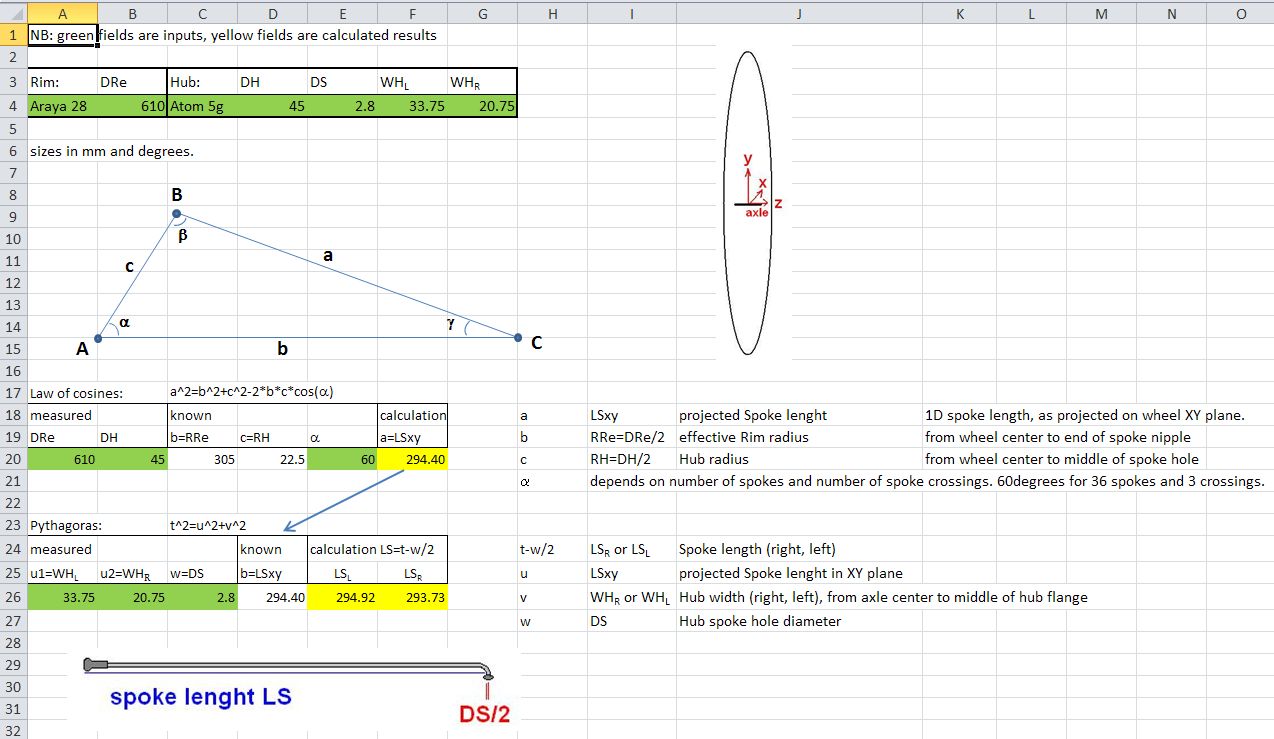

That gives us the following triangle in the XY-plane, where angle Alpha is 50+10=60degrees:

We can measure 'b' (effective rim radius) and 'c' (hub radius), and since we know 'Alpha' we can calculate 'a' (spoke lenght in XY-plane).

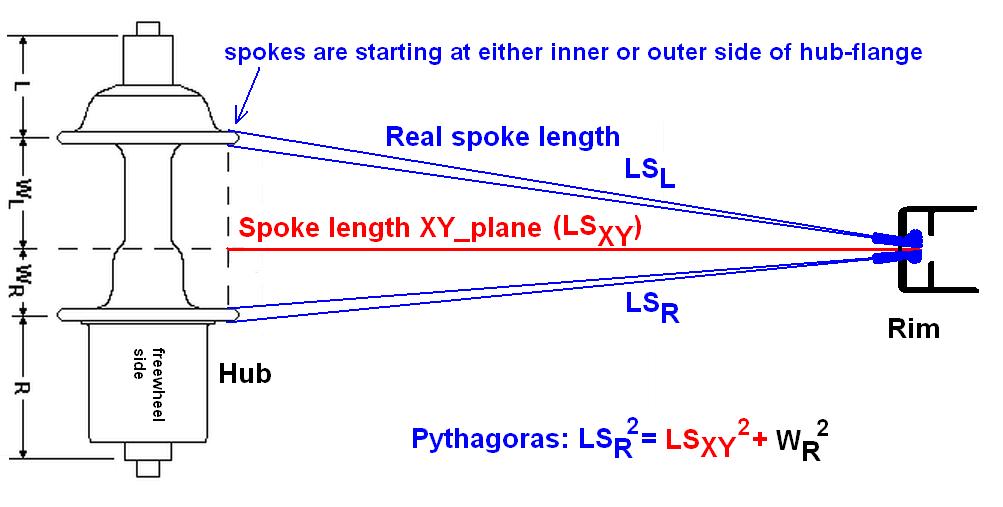

Next step is to look along the Z-axis. We can measure the values WL and WR of the hub, and together with the calculated XY_plane Spokelenght (LSXY), we can calculate the real spokelength with Pythagoras:

For a rearwheel with a freewheel, WR will be shorter than WL , and thus will the right spokes be approx 2mm shorter than the left spokes, so LSR and LSL have to be calculated separately.

The spokes on one side of the wheel are starting on either the inner or outer side of the hub-flange, but that gives such a little difference, that using the average (by measuring WR and WL to the middle of the hub-flange, as drawn in the picture above) is accurate enough.

Also the nipples being not exactly in the middle of the rim doesn't influence the spokelength enough to consider it in the calculation.

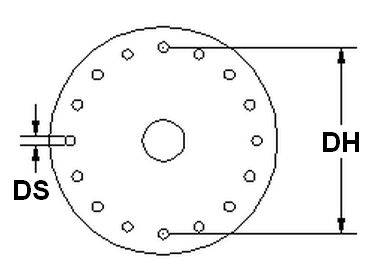

The size of the hole in the hub-flange has an impact on the spokelenght, so this must be included in the calculation.

#3 Measurements to obtain values for the calculation

You need the following measurements:

- Hub diameter, DH (For most standard hubs, the left and right sides have equal DH)

- Hub spokehole diameter, DS (normally 2.6mm)

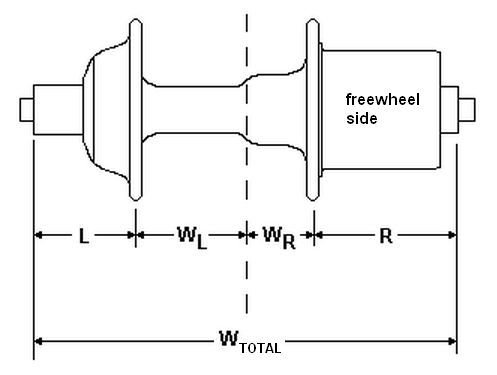

- Left hub-width, WL. This is measured easiest as (WTOTAL /2)-L

- Right hub-width, WR. This is measured easiest as (WTOTAL /2)-R

- Spoke angle Alpha, AS (60degrees for the case of a standard wheel with 36 spokes and 3 crossings)

- Effective rim diameter, DRe (description below)

|

|

The effective rim diameter (DRe) is defined as the distance between the ends of two opposite spokes, with the nipples screwed fully onto the spokes.

This is a definition that is very practical, clear, and easy to measure.

My favourite way of measuring DRe is by using two spokes of known length, mounted in opposite holes (count the holes to be sure!)

NB: the length of a spoke should be defined like this, with the nipple screwed on so far that the spoke end is just flush with the end of the nipple:

Measuring the length of a single spoke can be done accurately without the nipple, and using a metal ruler.

Measure the DRe at least two places and average the value, because the rim could be oval initially:

The length measured with he caliper plus the length of the two known spokes is the DRe.

Click on the screenshot to download an Excel spoke_length calculation spreadsheet, that uses the derivation from this page.

I have used this spreadsheet to build new wheels and also checked the results with some existing wheels (that I took apart for spareparts..), and it is amazingly accurate.

#4 Links to other sites about wheelbuilding

Here some links, so you can read about the things I didn't write on my page:

| good articles and other links: | more links: |

|

more coming soon |